- HOME

- NEWS

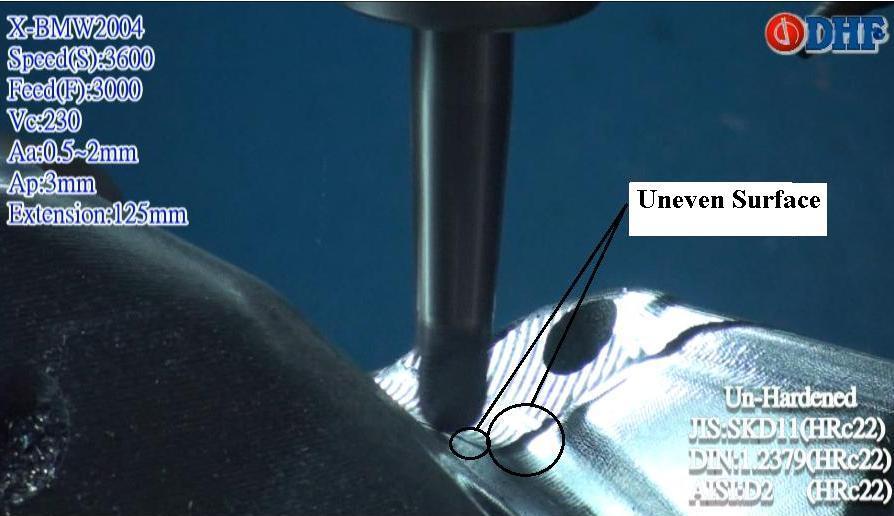

- X-BMW solves the problem of uneven surface successfully

X-BMW solves the problem of uneven surface successfully

2019.08.23.jpg)

Exchangeable Head Endmill <X-BMW1204>

<Demonstration for uneven surface of motor model>

Most automobile molds are larger molds, due to their shape of molds, they apply larger depth of cutting, and their roughing ways usually choose inserts.

After roughing, the corner or corner of smaller corner radius would have un-even surface.

Most operators select ball nose inserts or carbide ball nose end mills to apply semi-finishing,

the flutes would broke easily and decreases tool’s life during processing.

In order to overcome this difficulty, we invented ball nose end mill X-BMW, and tested in mold factory for half years.

X-BMW solves the problem of uneven surface successfully, not only increases the performance, but also extend tool’s life.

X-BMW has the following 3 advantages:

1.Four-flute-design is better than two-flute-design of inserts, has double performance than inserts.

2.Geometry appearance is interlaced zigzag design, well-executed of chip removal and low stickness.

3.The zigzag design disperses the counterforce of uneven milling, makes the cutter stronger, and has triple tool’s life than inserts.

The purpose of invention X-BMW, 2nd generation of exchangeable end mills are:

1.Increase performance.

2.extend tool’s life

3.Reduce costs of customer

4.Win-win future in the long term.

Written by DHF Technology Center