- HOME

- NEWS

- The warrior in high hard/high speed roughing machining-UEYR

The warrior in high hard/high speed roughing machining-UEYR

2019.08.23

The quality of tool itself is the key point in high hard cutting, extraordinary machining efficiency and

ideal tool life are the necessary conditions to achieve in the process.

For the need of machining, DHF Company especially design UEYR Cutter for roughing the material whose HRC ranges from 50 to 62.

It shows excellent result in high speed cutting and high performance cutting.

Below are introductions for the practical machining samples by DHF Technical Applications Center:

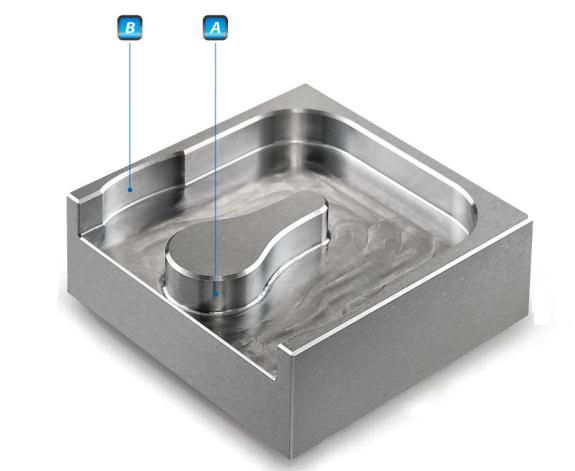

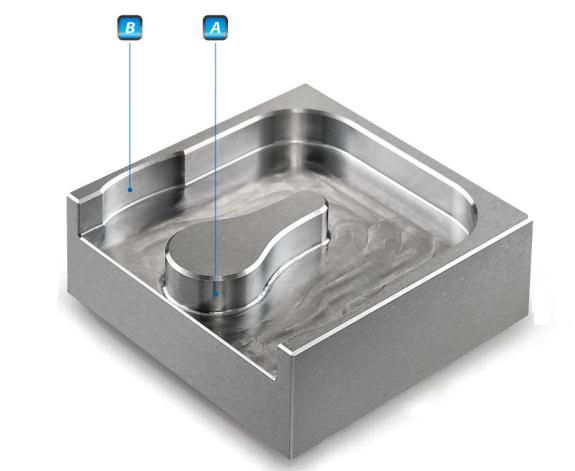

<Sample 1>: High Speed Cutting

Work material: JIS: DKD61//DIN: 1.2344(HRc52)

Material size: 80*80*30 mm

Machining cutter item: UEYR1010(Φ10*R1 mm)

Machining way: Mark A is slotting proceeding in high speed.

Mark B is side milling in high speed.

Milling statistics: Please notice Speed (S), Feed movement (FEED) and milling volume (Aa) and (Ap).

.JPG)

Total Machining Time: 3 minutes

<Sample1>

<Sample 2>: High Performance Cutting

In general concept, high hard material can’t achieve high performance cutting.

Moreover, most of the normal equipments contain low speed spindles,

so it can’t achieve high speed cutting (HSC) as well.

However, due to the special geometric figure for cutter design, the original machining limit is thoroughly broken.

The following pictures are sample 2 for UEYR1010(Φ10*R1 mm) to proceed machining to work material HRC 52 in 8D (8mm) side milling:

<Sample2>

Machining films of Sample 1 and 2 and be viewed on at DHF official website. (http://www.endmill.com.tw) )

Written by DHF Technology Center

ideal tool life are the necessary conditions to achieve in the process.

For the need of machining, DHF Company especially design UEYR Cutter for roughing the material whose HRC ranges from 50 to 62.

It shows excellent result in high speed cutting and high performance cutting.

Below are introductions for the practical machining samples by DHF Technical Applications Center:

<Sample 1>: High Speed Cutting

Work material: JIS: DKD61//DIN: 1.2344(HRc52)

Material size: 80*80*30 mm

Machining cutter item: UEYR1010(Φ10*R1 mm)

Machining way: Mark A is slotting proceeding in high speed.

Mark B is side milling in high speed.

Milling statistics: Please notice Speed (S), Feed movement (FEED) and milling volume (Aa) and (Ap).

.JPG)

Total Machining Time: 3 minutes

<Sample1>

<Sample 2>: High Performance Cutting

In general concept, high hard material can’t achieve high performance cutting.

Moreover, most of the normal equipments contain low speed spindles,

so it can’t achieve high speed cutting (HSC) as well.

However, due to the special geometric figure for cutter design, the original machining limit is thoroughly broken.

The following pictures are sample 2 for UEYR1010(Φ10*R1 mm) to proceed machining to work material HRC 52 in 8D (8mm) side milling:

<Sample2>

Machining films of Sample 1 and 2 and be viewed on at DHF official website. (http://www.endmill.com.tw) )

Written by DHF Technology Center