Introduction of HPC Series

2019.08.22

Working proficiently without any obstruction

High performance cutting is putting in use on 2D mass production.

And the application for High Performance Cutting Series is widely distributed on mass production.

As for mold machining, it takes more challenges on 3D processing. In order to seek for the breakthrough on this issue,

it takes DHF Technical Applications Center lots of time on experiences, eventually we made a huge progress on mold

machining as a great success to deal with it in the minimum time.

How can we define high performance cutting (HPC)? When the machining condition is a huge quantity of volume to be milled,

and it contains the high speed in Feed Movement (FEED), it would match what we so called High Performance Cutting (HPC).

Cutters for High Performance Cutting Series are mainly applied on achieving High Performance Cutting (HPC) whose

work material is below HRc 45, and it may vary with different working materials.

The followings instruction is the various features of each cutter:

Ⅰ. UEW-4T

1.Suitable work material:

A.Steel ranges from HRC 32 or below: carbon steel: S50C / SS400 :1.1210 / 1.0036 : 1050 /A570 Gr.45

2.Analysis for cutter range:

A.Special geometric cutter design and Vc (Cutting speed) can achieve at 150m/min or higher.

B.Slotting and side milling can achieve in 1D or above in machining.〈1D means 1* D (Cutter’s diameter) 〉

3.The sample picture for machining:

.png)

Medium carbon steel / S50C

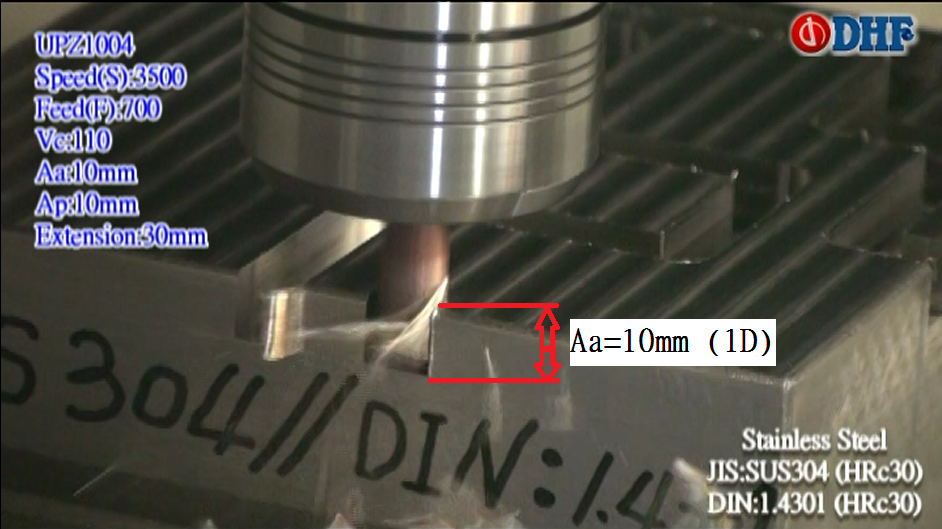

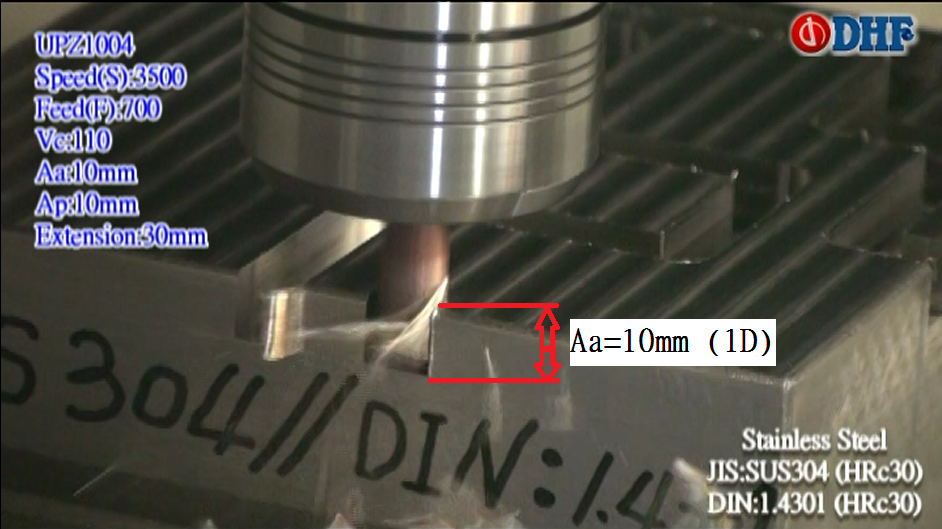

Ⅱ. UPZ // UPS

1.Suitable work material:

A. Steel whose HRC ranges from 45 or under: such as stainless steel (SUS304) / NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A. Special design for anti-seismic and groove shape to make it better in removing shavings and extending tool life.

B. Slotting and side milling can achieve in 1D or above in machining.

C. It’s suitable for roughing and finishing processes.

3.The sample picture for machining:

Stainless Steel(SUS304)

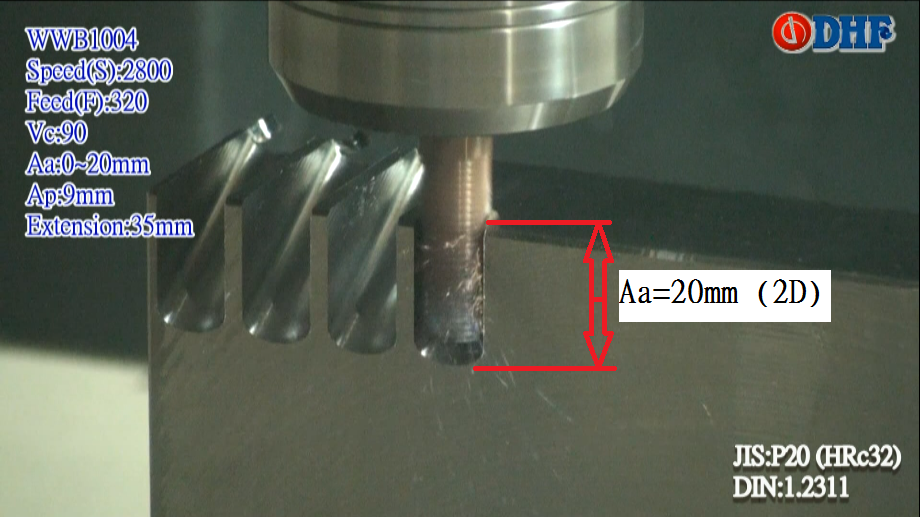

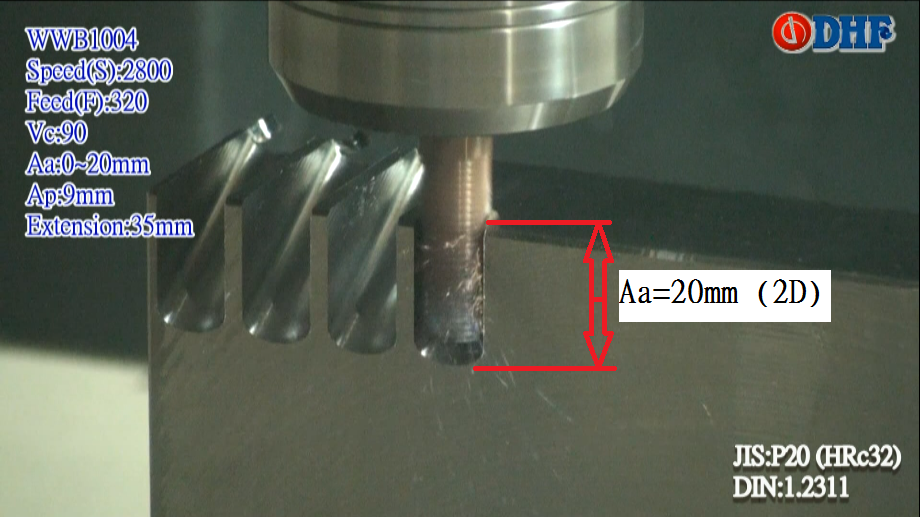

Ⅲ. WWB // WUB

1.Suitable work material:

A. Steel whose HRC ranges from 45 or under: such as Titanium alloy (Ti-AL-4V), Stainless (SUS304)/ NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A. Special design for anti-seismic and serrate shape to make it better in removing shavings and extending tool life.

B. Slotting and side milling can achieve in 1D or above in machining.

C. It’s suitable for blank and normal rough machining.

3.The sample picture for machining:

Machining < P20 // (1.2311)-HRc32 >

P20 // (1.2311)-HRc32

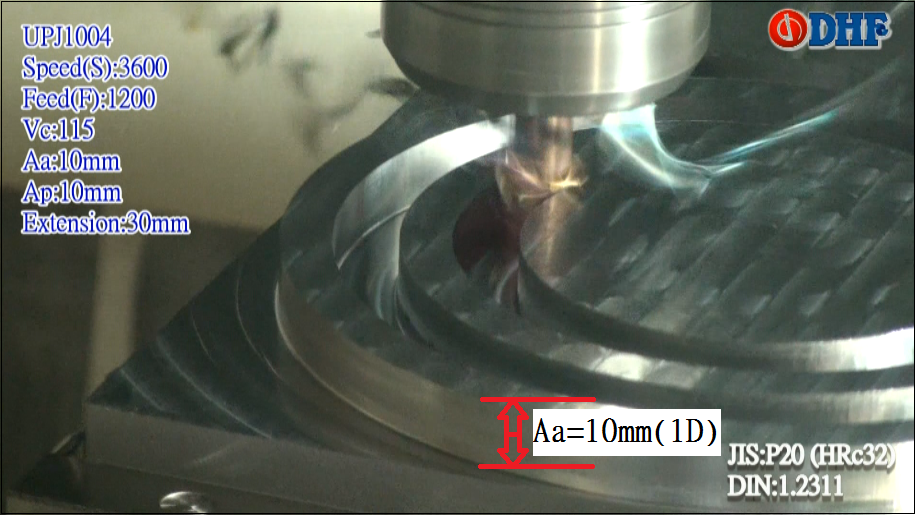

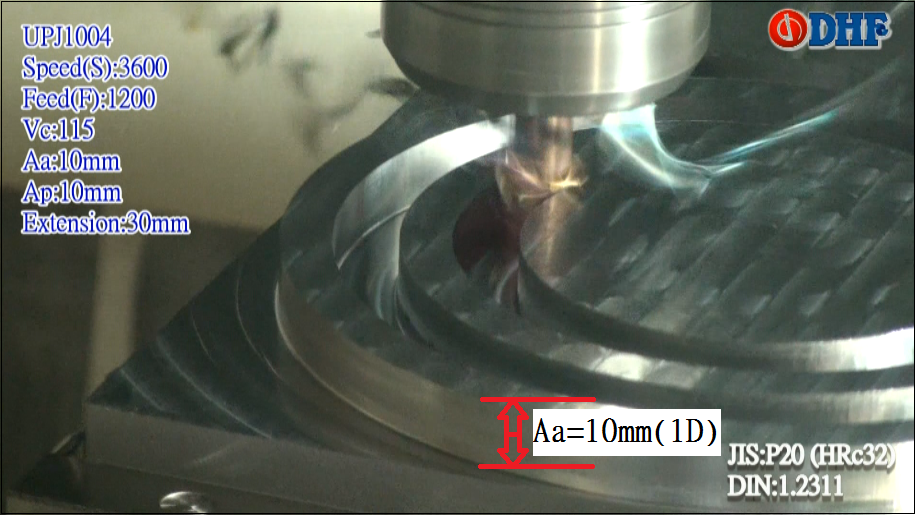

Ⅳ. UPJ

1.Suitable work material:

A.Steel whose HRC ranges is under 45: such as Stainless (SUS304)/ NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A.Special design for anti-seismic and serrate shape to make it better in removing shavings and extending tool life.

B.Slotting can achieve in 0.8D or above in machining.

C.It’s suitable for blank, finishing milling and 3D machining.

3.The sample picture for machining:

P20 // (1.2311)-HRc32

Introductions below are parts of the products to this Series, other items,

like UPJ // UPW // UPE // UPER // UPG- have outstanding performance

while in high performance machining.

All the sample videos for machining can be viewed at DHF official website: (http://www.endmill.com.tw)

Written by DHF Technology Center

High performance cutting is putting in use on 2D mass production.

And the application for High Performance Cutting Series is widely distributed on mass production.

As for mold machining, it takes more challenges on 3D processing. In order to seek for the breakthrough on this issue,

it takes DHF Technical Applications Center lots of time on experiences, eventually we made a huge progress on mold

machining as a great success to deal with it in the minimum time.

How can we define high performance cutting (HPC)? When the machining condition is a huge quantity of volume to be milled,

and it contains the high speed in Feed Movement (FEED), it would match what we so called High Performance Cutting (HPC).

Cutters for High Performance Cutting Series are mainly applied on achieving High Performance Cutting (HPC) whose

work material is below HRc 45, and it may vary with different working materials.

The followings instruction is the various features of each cutter:

Ⅰ. UEW-4T

1.Suitable work material:

A.Steel ranges from HRC 32 or below: carbon steel: S50C / SS400 :1.1210 / 1.0036 : 1050 /A570 Gr.45

2.Analysis for cutter range:

A.Special geometric cutter design and Vc (Cutting speed) can achieve at 150m/min or higher.

B.Slotting and side milling can achieve in 1D or above in machining.〈1D means 1* D (Cutter’s diameter) 〉

3.The sample picture for machining:

.png)

Medium carbon steel / S50C

Ⅱ. UPZ // UPS

1.Suitable work material:

A. Steel whose HRC ranges from 45 or under: such as stainless steel (SUS304) / NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A. Special design for anti-seismic and groove shape to make it better in removing shavings and extending tool life.

B. Slotting and side milling can achieve in 1D or above in machining.

C. It’s suitable for roughing and finishing processes.

3.The sample picture for machining:

Stainless Steel(SUS304)

Ⅲ. WWB // WUB

1.Suitable work material:

A. Steel whose HRC ranges from 45 or under: such as Titanium alloy (Ti-AL-4V), Stainless (SUS304)/ NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A. Special design for anti-seismic and serrate shape to make it better in removing shavings and extending tool life.

B. Slotting and side milling can achieve in 1D or above in machining.

C. It’s suitable for blank and normal rough machining.

3.The sample picture for machining:

Machining < P20 // (1.2311)-HRc32 >

P20 // (1.2311)-HRc32

Ⅳ. UPJ

1.Suitable work material:

A.Steel whose HRC ranges is under 45: such as Stainless (SUS304)/ NAK80(1.2083) / P20(1.2311) / S50C(1.1210).

2.Analysis for cutter range:

A.Special design for anti-seismic and serrate shape to make it better in removing shavings and extending tool life.

B.Slotting can achieve in 0.8D or above in machining.

C.It’s suitable for blank, finishing milling and 3D machining.

3.The sample picture for machining:

P20 // (1.2311)-HRc32

Introductions below are parts of the products to this Series, other items,

like UPJ // UPW // UPE // UPER // UPG- have outstanding performance

while in high performance machining.

All the sample videos for machining can be viewed at DHF official website: (http://www.endmill.com.tw)

Written by DHF Technology Center