- HOME

- NEWS

- Stainless Steel Series introduction.

Stainless Steel Series introduction.

2019.07.31

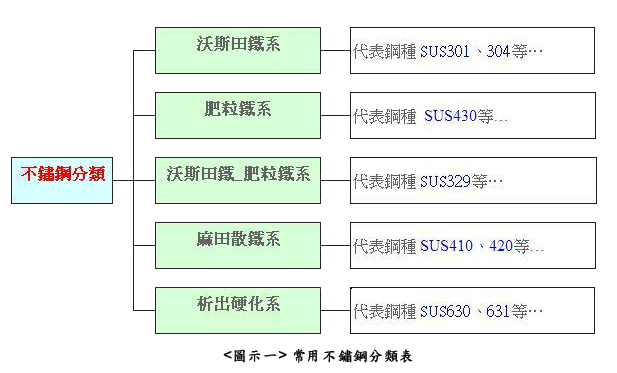

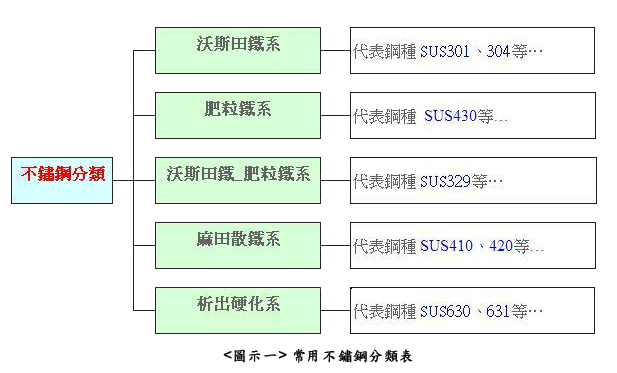

Because Stainless steel has superior featured abilities of erosion, shapes, tolerance and tenacity, it has wide applications on heavy and light industry, supplies industry and architecture decorations.

.png)

The most used stainless steels are SUS303, SUS304, and SUS316, because of their high ability on erosion and strong tenacity; it would have problem of radiation, material hardened, and chip stickness, those problems make it much harder to cut.

In order to overcome the difficult features of stainless steel, the material, coating and geometry design are keys factors.

1. For stainless steel cutting, not only well-executed and smooth of chip removal, also away with radiation, decrease the problem of hardened material.

2.Most stainless steel milling takes wet coolant, the suitable coating is G10.

3.High helix angle groove R and anti-vibration design; when high performance milling, the cutting speed Vc could reach to 100-120 m/min, and it is able to 1D machining for both slotting and side milling.

Because the different demands of end mill selection to customers, here we have the recommendations based cutter’s performance and life:

First selection:

<UPZ> <UTH> <UTHR> <UPS> <UPJ> <WWB>

Second selection:

<UPE> <UPER> <UPG>

Third selection:

<ETH> <ETB> <RTB> <WWA>

Written by DHF Technology Center

.png)

The most used stainless steels are SUS303, SUS304, and SUS316, because of their high ability on erosion and strong tenacity; it would have problem of radiation, material hardened, and chip stickness, those problems make it much harder to cut.

In order to overcome the difficult features of stainless steel, the material, coating and geometry design are keys factors.

1. For stainless steel cutting, not only well-executed and smooth of chip removal, also away with radiation, decrease the problem of hardened material.

2.Most stainless steel milling takes wet coolant, the suitable coating is G10.

3.High helix angle groove R and anti-vibration design; when high performance milling, the cutting speed Vc could reach to 100-120 m/min, and it is able to 1D machining for both slotting and side milling.

Because the different demands of end mill selection to customers, here we have the recommendations based cutter’s performance and life:

First selection:

<UPZ> <UTH> <UTHR> <UPS> <UPJ> <WWB>

Second selection:

<UPE> <UPER> <UPG>

Third selection:

<ETH> <ETB> <RTB> <WWA>

Written by DHF Technology Center